Product Description

1

Name: Made in china customized cast iron rigid hydraulic fitting pipe fittings grooved coupling

Min order: 1000 pcs

Packing: export standard packing

Customized production is available as your drawings or sample.

| Process | Sand Casting, Investment Casting | |

| Material | Malleable Iron , Ductile Iron | |

| Weight | 0.1Kg~200Kg | |

| Testing instrument | composition testing | Spectrometer, Metallographic microscope |

| Performance testing | Hardness tester, Tensile testing machine | |

| Size Measuring | Vernier Caliper, Depth Caliper, feeler gauge,Thread Gauge , Height Gauge | |

| Roughness | Ra1.6~Ra6.3 | |

| Machining Equipment | CNC Center , CNC Machines, Turning, Drilling, Milling, Boring machine,Grinding Machines, | |

| Wire EDM,Laser Cutting&Welding, Plasma Cutting &Welding, EDM etc. | ||

| Quality control | Sampling inspection of raw materials and semi-finished products, 100% Inspection of finished products | |

| Surface Treatment | Sand Blast , Painting, Coating, Galvanized , Hot Galvanized | |

| Production Capacity | 60000T / Years | |

| Lead Time | Normally 30 – 45 Days. | |

| Payment Terms | T/T , L/C | |

| Material Standard | ASTM , AISI , DIN , BS, JIS, GB, | |

| Certification | ISO9001:2008, IATF16949:2016 | |

2

About quality

We insist that the survival of the company should depend on the products quality continuous improvement, without which we cannot survive for long.

Our product quality control system

Quality control involves the inspection and control of incoming materials, production process and finished products.

1 Firstly, metallurgical microscope analysis is performed on randomly sampled incoming materials to ensure that the chemical composition meets the production requirements.

2 Then, during the production process, there are QC personnel to conduct timely spot checks to ensure that the product is free of defects during the manufacturing process and to coordinate and handling of any abnormal quality issues that may arise.

3 The final step in the production process is a magnetic particle detector for metal parts to detect hidden cracks or other defects.

4 All the finished metal parts is sampled in proportion and sent to the laboratory for various mechanical property tests and dimensional measurements, and the surface quality is manually 100% inspected.

5 About the quality management system, we strictly carry out system management in accordance with ISO9001 and TS16949 quality standards and 5S lean production management is implemented on the production site.

3

Our Advantages:

1 We have a complete production process and equipment research and development capabilities for ferrous metal forming. Over 25 years of production experience of forging equipment and casting equipment make us own deep level understanding and operating of all equipments’ performance and running.

2 Our parent company, HiHangZhou Group, is a world-renowned high-end machinery manufacturing enterprise with more than 30 domestic subsidiaries and branches. The sales volume of 4 products ranks No1 nationwide and even worldwide, providing us with a strong technical and financial support.

3 One-third of over 300 staff are technical R&D members, ensuring the continuous technical innovation and the sustainable development of our company.

4 Our company implements the employee stock ownership system of company shares Increasing members’ sense of responsibility, creativity and work motivation.

5 The company is a model enterprise in the region of low-carbon environmental protection, and energy saving and emission reduction in reduction.

6 Unique company culture, and the regular rotation of individual work position give full play to the potential of talents and provide strong vitality for the development of the company.

7 Our Service:

A. Customized and Standard Manufacturing Service

B. A variety of Manufacturing Process Integration

C. Quality and Delivery Time Guaranteed

D. Effective Communication Ability

5

Company Culture

Our Vision

To become 1 of the leading companies

Our Mission

To become a platform for employees to realize their dream

To become 1 of the transforming and upgrading pacemaker of Chinese enterprises

To set the national brands with pride

Our Belief

Strive to build the company into an ideal platform for entrepreneurs to realize their self-worth and contribute to the society

Values

Improvement is innovation, everyone can innovate

innovation inspired and failures tolerated

6

FAQ

1.

Q: Are you a trading company or a manufacturer?

A: Obviously we are a manufacturer of forging products, casting products and also have a high level of machining capabilities.

2.

Q: What series products do your have?

A: We are mainly engaged in forming processing of ferrous metals, including processing by casting , forging and machining. As you know, such machinery parts can be observed in various industries of equipment manufacturing.

3

Q: Do you provide samples? is it free?

A: Yes, we commonly provide samples according to the traditional practice, but we also need customers to provide a freight pay-by-account number to show mutual CZPT of cooperation.

4

Q: What is your minimum order quantity?

A: Yes, we require all international orders to have an minimum order quantity. The quantity is up to the exact products feature or property such as the material, weight, construction etc.

5

Q: What is the lead time?

A: Generally our forging products and casting products need to make new dies or molds, the time of making new dies or molds and samples within 30-45 days, and the large batch production time within 30-45 days. it’s also according to the parts structural complexity and quantity.

6

Q: What kinds of payment methods do you accept?

A: You can make the payment by T/T or L/C. 30% deposit in advance, 70% balance against the copy of B/L.

| After-sales Service: | 1 Years |

|---|---|

| Warranty: | 1 Years |

| Connection: | Press Connection |

| Structure: | Universal |

| Flexible or Rigid: | Rigid |

| Material: | Iron |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by CX 2023-04-20

China manufacturer & factory supplier for Stroke in Matola Mozambique Hydraulic Tie Rod Cylinder 2.5" X 24" With high quality best price & service

Distributor of precision roller chains created from carbon steel. Offered with .two hundred to 1.875 in. roller dia. Flat prime, multi-flex and conveying chains are also supplied.we source chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes and many others.

Overview

Fast Specifics

- Warranty:

-

one Calendar year

-

Soon after Warranty Provider:

EPG Digital specializes in specific, substantial-functionality generate solutions. We offer a wide selection of integrated motors, brushless DC motors and stepper motors, as nicely as motor controllers and linear actuators that are mainly utilised in automation systems, computerized laboratory tools and medical devices. -

On the internet assistance

- Regional Service Location:

-

None

- Showroom Place:

-

None

- Brand Title:

-

OEM

- Area of Origin:Zhejiang, China

- Strain:

-

–

- Construction:

-

–

- Certification:

-

–

- Weight:

-

–

It is our goal to offer a extensive assortment of good quality items at inexpensive charges, offer the greatest provider for clients content and contribute to our ongoing improvement.

- Energy:

-

–

- In our product sales plan we supply regular and vast-angle PTO push shafts. Concerning the customers’ needs there are different measurements, lengths and basic safety factors (clutches) accessible. Dimension(L*W*H):

-

–

- After-revenue Service Offered:

-

OEM

- Neighborhood Services Location:

-

United States

- -:

-

–

- Problem:

-

New

- Variety:

-

OEM

Provide Potential

- Supply Capacity:

- 10000 Unit/Units for every Month

Packaging & Delivery

- Packaging Details

- Wooden Situation

- Port

- Shanghai/ Ningbo

-

Lead Time

: -

Amount(Units) 1 – 10000 >10000 Est. Time(days) 35 To be negotiated

On-line Customization

Item Description

Stroke Hydraulic Tie Rod Cylinder 2.5″ X 24″

|

Brand Title: |

Stroke Hydraulic Tie Rod Cylinder 2.5″ X 24″ |

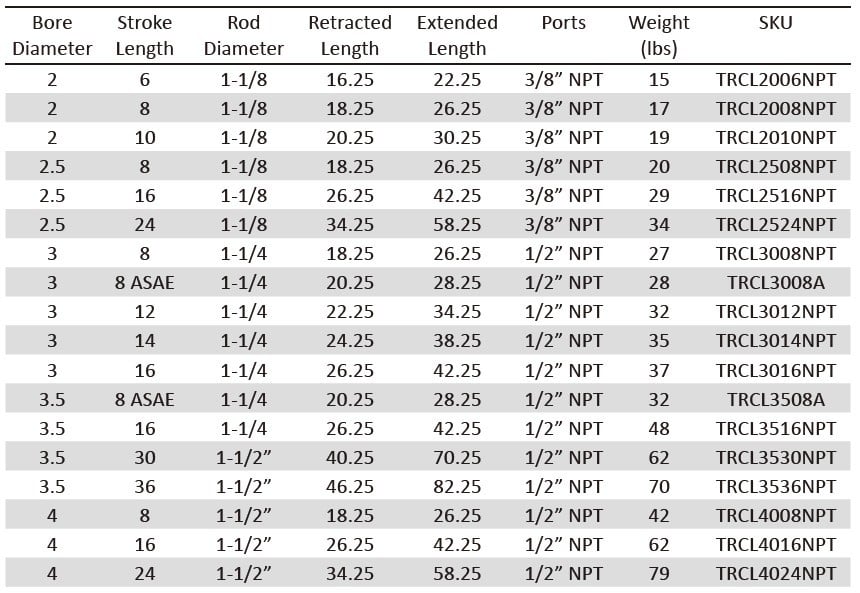

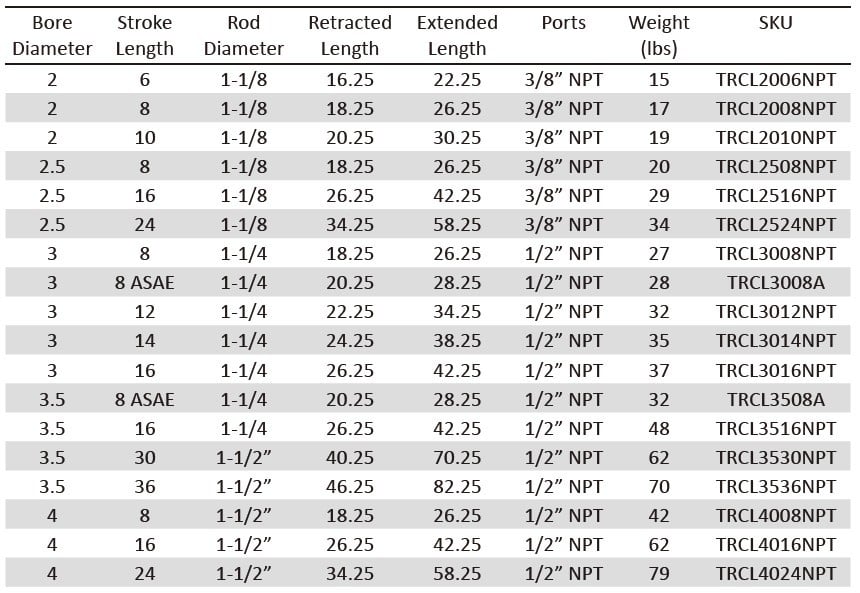

two.5″ Bore x 24″ Stroke Hydraulic Tie Rod Cylinder

– 2500 psi – 3/8″ NPT Ports –

– 2.5″ Bore

– 24″ Stroke

– 2500 PSI Operating Force

– 1-1/8″ Rod Diameter (piston

– 34-1/4″ Retracted Dimension (Centre of Pin to Centre of Pin)

– fifty eight-1/4″ Prolonged Dimension (Middle of Pin to Center of Pin)

– 3/8″ NPT (Pipe Thread) Ports

– 1″ Clevis Pin Diameter

– 1 Year Substitute Warranty

Our Company

Grinding Workshop

CNC Tooth Machine

CNC Lathe Workshop

Figuring Middle

CNC Workshop

Warmth Remedy Equipment

3D Measurement Machinery

Equipment Teeth Profile Take a look at Devices

Heat Therapy Workshop

Tooth Profile Workshop

Materials obtainable

Reduced carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless metal. Can be tailored concerning consumer demands.

Area treatment method

Blacking, galvanization, chroming, electrophoresis, colour portray, …

Heat therapy

Large frequency quenching heat treatment, hardened tooth, carbonizing, nitride, …

Certifications

FAQ

Q: Are you trading company or maker ?

A: Our group consists in 3 factories and 2 abroad product sales businesses.

Q: Do you give samples ? is it free or extra ?

A: Yes, we could provide the sample for free of charge demand but do not shell out the value of freight.

Q: How extended is your delivery time ? What is your conditions of payment ?

A: Generally it is forty-45 times. The time may vary dependent on the item and the degree of customization. For regular goods, the payment is: thirty% T/T in progress ,equilibrium ahead of shippment.

Q: What is the actual MOQ or cost for your solution ?

A: As an OEM business, we can give and adapt our goods to a wide assortment of demands.Therefore, MOQ and price might significantly fluctuate with dimension, material and even more requirements For instance, high priced merchandise or normal products will generally have a reduced MOQ. Please contact us with all pertinent particulars to get the most accurate quotation.

If you have an additional concern, remember to truly feel free of charge to contact us.

Packing & Delivery

Providers

Also I would like to get this chance to give a transient introduction of our At any time-Electrical power organization:

Our business is a famous company of agriculture gearbox,worm lessen gearbox, PTO shafts, Sprockets ,rollar chains, bevel equipment, pulleys and racks in china.

We have exported several goods to our clients all over the world, we have prolonged-time experience and sturdy technologies assistance.

Some of our client :

Italy: COMER,GB GEABOX ,SATI, CHIARAVALLI, AMA , Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies

Brazil: AEMCO ,STU

United states of america: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-Ø Our Firm with above twelve year’s heritage and one thousand personnel and twenty income.

-Ø With in excess of a hundred Million USD product sales in 2017

-Ø With advance machinery equipments

-Ø With large perform ability and high top quality control, ISO certified.

……

you also can check our site to know for much more information, if you want our items catalogue, remember to speak to with us.